E-Catalog > SEAL Analytical > Soil Particle Size Distribution Robot

Product Information :

- เครื่องมือวิทยาศาสตร์ / สารเคมีและวัสดุภัณฑ์สำหรับห้องปฏิบัติการ

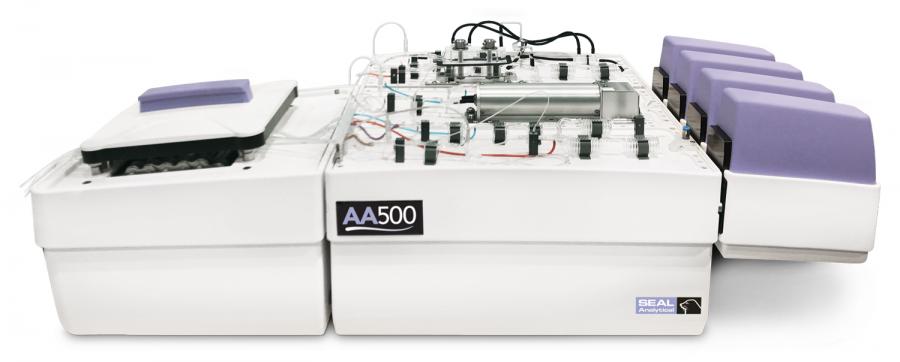

- SEAL Analytical

- สินค้า, ผลิตภัณฑ์

Product Detail :

Product Overview

The Soil Particle Distribution Robot offers a reliable, fast, and cost-effective solution for automating key steps in soil analysis according to ISO 11277. Designed to streamline the measurement of mineral particle proportions in soil, it provides flexible automation options tailored to your needs.

The process can be fully or partially automated using 3 independent robots, each handling a specific step:

- Sample Preparation Robot: Automates sample tracking, precise reagent dosing, and conductivity measurements.

- Sample Collection Robot: Efficiently manages sample retrieval, mixing, and optional weighing, with controlled evaporation features.

- Weighing Robot: Handles sample drying and precise weight measurements, with automated weighing and clay fraction calculations.

These robots can be acquired separately or combined for a fully automated workflow. With additional configuration possibilities, you can customize the setup to fit your lab's requirements. Discuss your specific needs with our sales team to find the perfect solution.

Why select the Soil Particle Distribution Robot?

Automation

- XYZ Robotic System: Automates the precise dosing of multiple reagents (hydrogen peroxide, hydrochloric acid, calcium chloride, water, antifoam) into sample holders.

- Programmable Dosing Cycles: Allows customization of step size (0.2ml to 5ml) and time intervals (90 sec to 3600 sec), automating the reagent addition process.

- Batch Processing: The system processes up to 40 samples per batch with minimal human intervention, automating nearly all aspects of sample preparation and treatment.

Compliance

- Precise Dosing and Temperature Control: Ensures consistent sample treatment, helping labs meet compliance standards for accurate and reproducible results.

- Customizable Settings: Allows labs to set exact volumes for hydrogen peroxide, hydrochloric acid, calcium chloride, and antifoam for each sample, supporting adherence to specific procedural guidelines.

- Fume Hood Compatibility: Ensures safe operation in a controlled environment, complying with safety regulations for handling volatile or hazardous materials.

Efficiency

- Batch Size and Operation Time: Capable of processing multiple batches daily (up to 40 samples per batch) due to the automated 7-hour hydrogen peroxide dosing cycle, maximizing throughput.

- Walkaway Operation: Minimizes human involvement by automating long-duration dosing and heating cycles, freeing staff for other tasks.

- Integrated Dosing Units: Efficiently handles multiple reagents with specific dosing units, optimizing the process for accuracy and speed.

Support

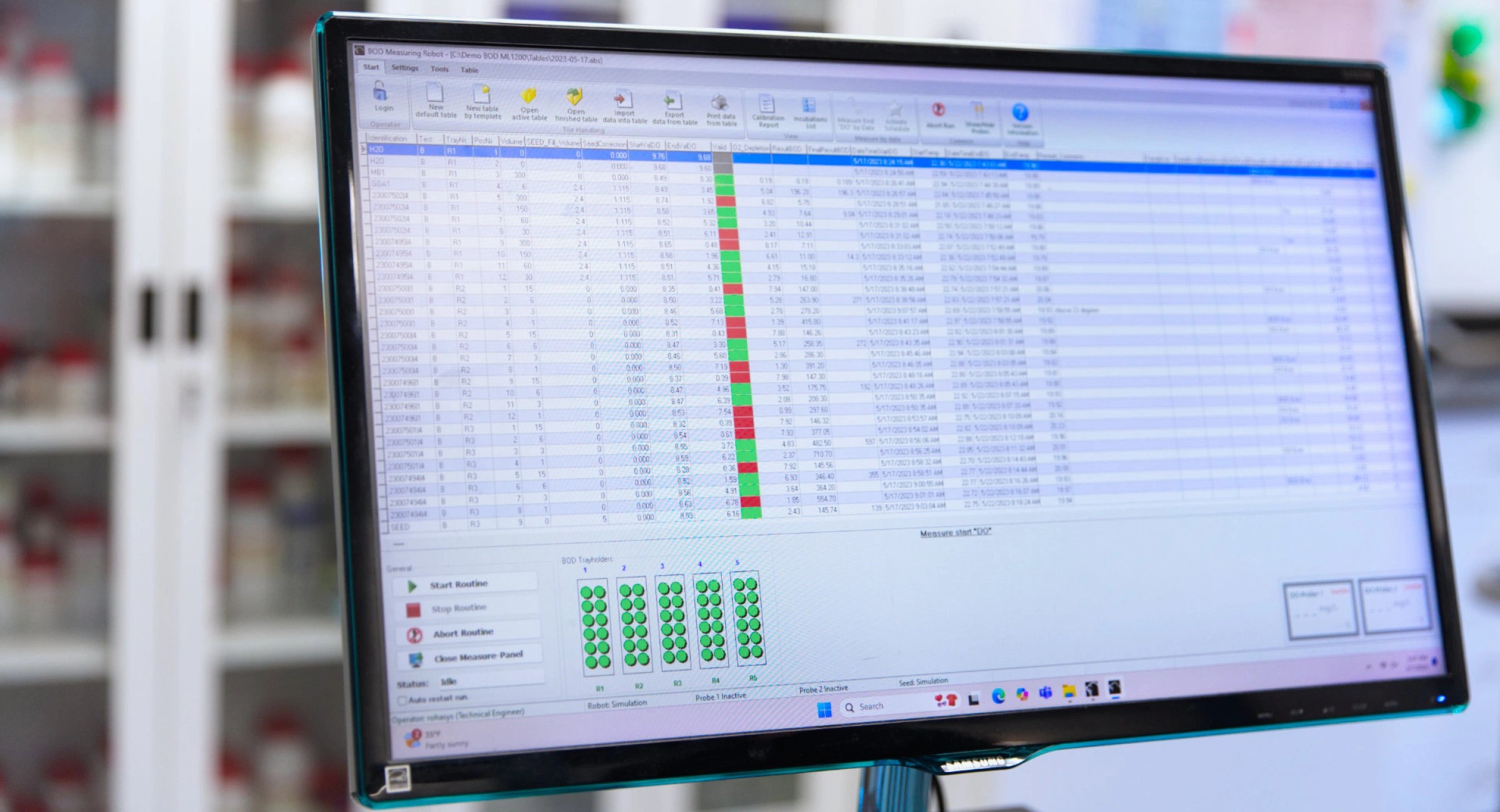

- PC-Controlled System: Easy-to-use software interface outside the fume hood provides full control over the entire process.

- Pre-configured Settings for Each Sample: Reduces the potential for user error and ensures support for consistent operations.

- Robust Construction: The system is built to withstand harsh chemical environments, requiring minimal maintenance and offering long-term reliability. This enhances overall lab support by reducing downtime.

Intuitive software for a tailored experience

The software is designed to manage precise timing and pipetting required for this analysis. Different fractions, with corresponding settling times, dosing, and flushing parameters, can be set up flexibly to meet your requirements. This setup allows analysts to easily prepare and execute runs using preset templates. Integration with your lab’s LIMS facilitates simple import and export of sampling data, procedures, and preferences. Additionally, new samples can be introduced at any time, enabling continuous analysis outside working hours and allowing the robot to operate around the clock.

This will reduce the lead time of analysis compared to manual handling during working hours.