GS-Tek offers a variety of ferrules for many GC brands. Ferrule materials include graphite, vespel and PTFE. Graphite ferrules are commonly used in GC instrumentation. Vespel/graphite ferrules are typically used for GC-MSD. PTFE ferrules are typically used for gas connections at ambient temperatures.

Ferrules are typically used in the hot sealing of columns, inlets and detectors, and they can also be used for gas connections. Ferrules are made of graphite, Vespel™, metal and PTFE materials. Ferrule dimensions are outside diameter (OD), internal diameter (ID), and length. V/G ferrules are often used for low bleed need application such as GC-MSD. To ensure seal reliability, V/G ferrules are single-use components. Graphite ferrules are used for a general GC application and can be reused a small number of times. Vespel ferrules are used for hard sealing, and PFTE are used for general connection at low temperatures (below 150℃).

Temperature limit of Ferrules

| Material |

Temperature limit |

| Graphite no binder |

400℃ |

| V/G |

350℃ |

| Vespel |

350℃ |

| PTFE |

150℃ |

Silicone-based septa are typically used for both GC inlet seals and sample introduction. They have a centered hole for guiding the syringe needle. Quality and performance of septa have a direct effect on application results (reliability and accuracy), column lifetime and instrument condition. A good practice is to check and change septa as often as needed.

● Septa are made of two different processed silicone material: Advance Green (AG) and Bleed and Temperature Optimized (BTO). BTO temperature limit is 400.C, and AG temperature limit is 350.C. Both are preconditioned and ready to use.

● Packaged in a glass jar. Septa are offered in different sizes depending on the GC instrument configurations. Check the GC instrumentation specifications for details.

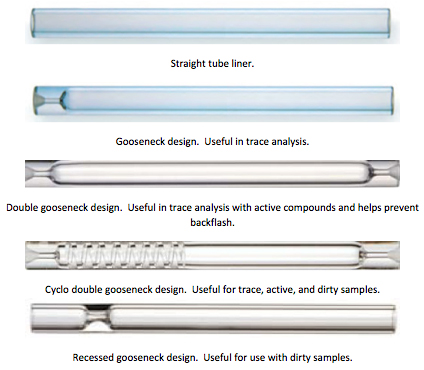

Glass-made GC inlet liners provide chambers sample vaporizing and sample introduction into the column. Liners are the centerpieces of the inlet system and have a direct impact on application reliability and accuracy. It is recommended to change these liners as needed, to minimize the accumulation of carry-over contaminates inside them. Such accumulation can reduce peak height, cause peak tailing or generate ghost peaks.

Liners come in different lengths, diameters (OD/IDs), shapes, and surface deactivation for different instruments, sampling and applications. Choose your liner carefully to fitting both your instrument and application. For popular split injection applications, a single taped liner with a silanized glass wool insert is recommended, which should be used as much as possible to improve application result. For heavy boiling point samples such as petroleum, an LTV or PTV liner with a narrow volume is often selected. For samples containing active components such as strong base/acid, a straight-shaped liner is suggested. For most applications, regular liners have sufficient inertness for sample introduction to column. For aqueous samples, a large volume liner is recommended.

Sample Injection Volume (ul) Recommended Liner ID (mm)

More than 1 ul 4 mm (vol~800ul)

Less than 1 ul 2 mm (vol~200ul)

GS-Tek offers a broad range of microliter syringes for several autosampler brands. Please use our syringe filter to quickly find the appropriate syringe for your needs. We also offer removable needle syringes which are autoclavable when disassembled. These manual syringes can be used for Shimadzu autosampler, and manual injections for gas samples and HPLC.

We offer inline gas filter that can remove common contaminates such as oxygen, moisture, and hydrocarbons from GC carrier and detector gases. Our inline gas filters are available in different sizes and configurations.